Your Resource for Sleep Health and Wellness

At Liquid Filling Machine, we are dedicated to helping you understand and navigate the complexities of sleep health.

Our Services

We are committed to providing comprehensive and reliable information on sleep health and testing.

Whether you’re exploring the cost of a sleep test, seeking a reputable sleep study clinic, or gathering information on CPAP sleep studies, you’ve found the right resource.

years of

experience

experience

0

Our experience

At Liquid Filling Machine, we bring years of expertise and a deep understanding of sleep health to help you navigate the complexities of sleep studies and treatments.Our experience in the field ensures that you receive accurate, reliable, and up-to-date information to make informed decisions about your sleep health journey.

- Expertise in Sleep Health

- Comprehensive Knowledge of Sleep Studies

- In-Depth Machine Reviews

About us

Why Choose Us

- Reliable Information: We pride ourselves on offering accurate and thoroughly researched content, making sure you have the information you need to make informed decisions about your sleep health.

- Comprehensive Resources: From cost analysis to machine reviews, Air Liquide Healthcare is your one-stop resource for all your sleep health needs.

- Expert Support: Our team of sleep health experts is here to provide personalized advice and consultations tailored to your unique needs.

“

"Finding the right sleep study clinic can be challenging, but Liquid Filling Machine made it straightforward. Their locator service and clinic reviews were invaluable in helping me select a top-notch facility. The personal consultation service was also very supportive. Highly satisfied with the experience!."

Laura K.

POSTS

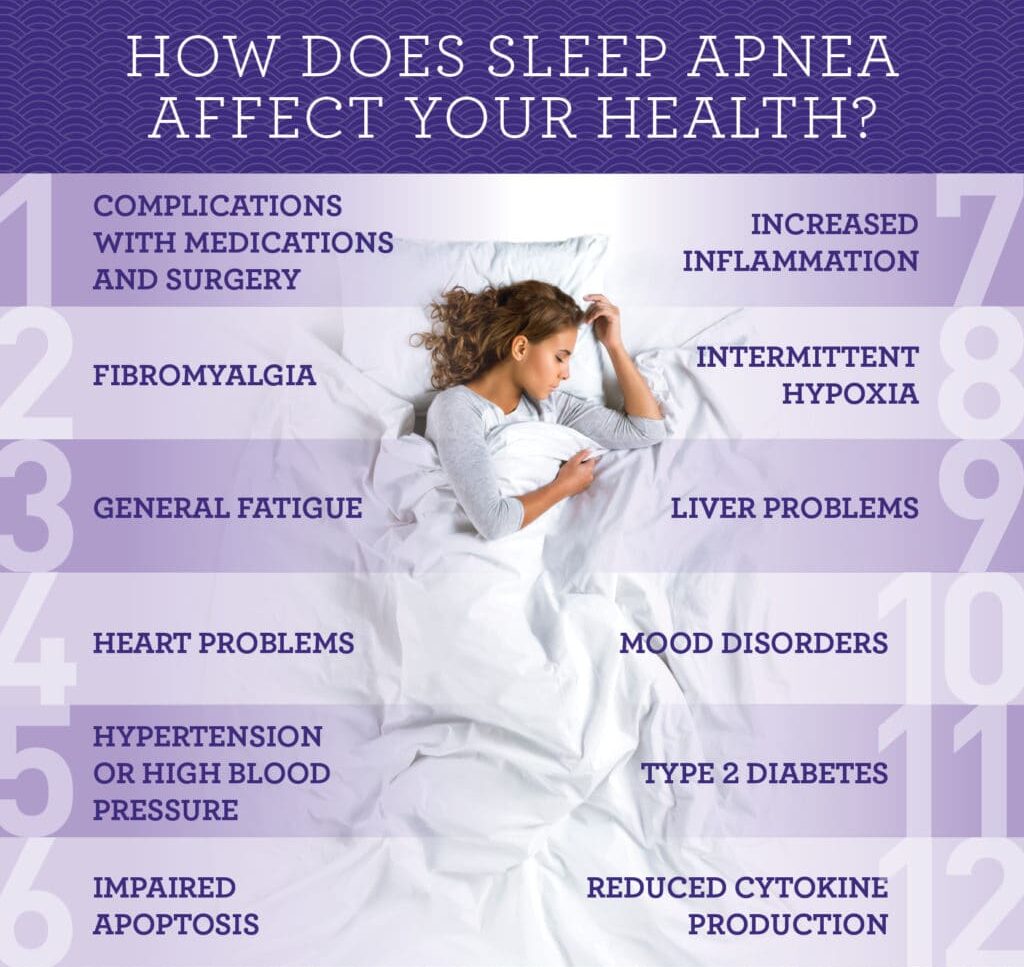

For individuals struggling with sleep apnea or other sleep-related issues, a Continuous Positive...